Product Information

注目製品

-

圧電応用製品群

超音波カッター『FUC01A』デモ機貸し出し対応開始のご案内

-

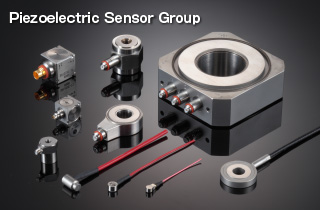

圧電センサ群

JCSS校正サービス(振動加速度)を始めました

-

圧電素子製品群

[新材料] ハード系PZT「C-25材」のご紹介

-

圧電応用製品群

ボルト締めランジュバン型振動子 使用例(超音波カッター)のご紹介

-

圧電センサ群

[新製品] 簡易感度校正器「MC-30」のご紹介

製品

Our Strengths

- Our strengths and pride in piezoelectric ceramics and sensors

- The technology and expertise, nurtured in the picturesque surroundings of Mt. Fuji, contributes significantly to society.

In our daily lives, products seamlessly integrate the enduring principles of piezoelectricity and ultrasonic technology, with their roots traced back over time. From healthcare and automotive applications to a variety of industrial sectors, they play a vital role in a diverse array of fields, showcasing their long-standing significance and widespread use.

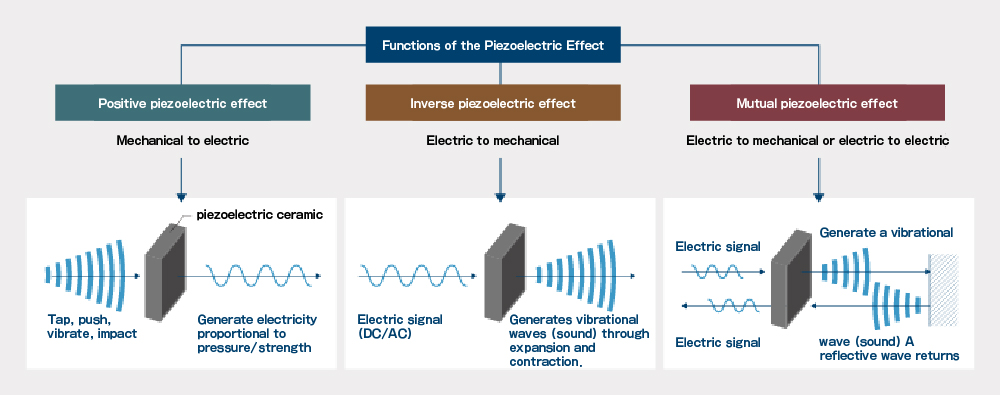

While piezoelectric ceramics themselves are not typically visible in our daily lives, they have various applications. Piezoelectric ceramics convert pressure and electricity, producing electrical output when subjected to deformation, and experiencing expansion or contraction when given electrical input. These characteristics enable them to be utilized for a wide range of purposes.

Surrounded by the beautiful nature of Fujinomiya, FUJI CERAMICS has honed its specialized expertise in piezoelectric ceramics and sensors over many years. This craftsmanship has been embraced by a diverse range of customers across various fields.

Production factories

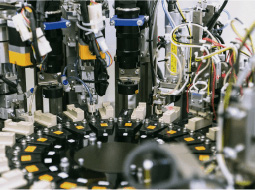

- Integrated production at specialized factories, ranging from a single unit to mass production.

- FUJI CERAMICS builds automated equipment utilizing jigs and robots to create manufacturing system tailored to the scale of production.

Each factory has an integrated production system, starting from the formulation of raw materials for piezoelectric ceramics.

Each factory has an integrated production system, starting from the formulation of raw materials for piezoelectric ceramics.

This incorporates production processes that leverage proprietary technologies integral to high-quality manufacturing.

FUJI CERAMICS is committed to meeting diverse customer needs, whether it’s creating specialized items, producing high-mix, low-volume products, fulfilling custom orders for single items, or handling large-scale production of several million units.

Management system

- Management system ensuring the quality of piezoelectric ceramic products.

- Diverse processes, starting from powder raw materials are supported by a “quality-driven” manufacturing system.

Raw materials for piezoelectric ceramics include lead zirconate titanate [Pb(Ti,Zr)O3], lead titanate [PbTiO3], lead metaniobate [PbNb2O6], and bismuth titanate [Bi4Ti3O12].

Raw materials for piezoelectric ceramics include lead zirconate titanate [Pb(Ti,Zr)O3], lead titanate [PbTiO3], lead metaniobate [PbNb2O6], and bismuth titanate [Bi4Ti3O12].

The starting raw materials are all oxides. The main raw materials and additives are blended, and the mixture undergoes the ceramic-making process.

A variety of processes such as micro-mixing management, refinement, powder molding, high-temperature sintering at 1200ºC, precision machining, electrode metallization, high-voltage processing, and testing/inspection are labor-intensive. High quality is assured through a management system, utilizing both manual and robotic handling, as well as testing and inspection devices for verifying the results.

本社:0544-58-4651 国内営業一課:0544-55-1701 国内営業二課:0544-55-1702 海外営業課:+81-544-58-4466

受付時間 8:00-17:00 土日祝を除く